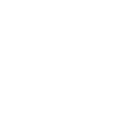

The SFB high-air-volume axial flow fan has undergone comprehensive upgrades based on the SF model, equipped with aluminum alloy sickle-shaped blades. It adopts an aluminum alloy casing to enhance the motor’s sealing performance, featuring low noise, large air volume, high wind pressure, excellent heat dissipation, and stable operation.

The SFG Series High-Temperature Axial Fan is upgraded from the SF model with a redesigned impeller and adopts an aluminum alloy casing to enhance the motor’s sealing performance,The motor incorporates high-temperature enameled wire, high-temperature bearings, and high-temperature lead wires. Consequently, this product can operate in environments with elevated temperatures (ambient temperature ≤100°C) or high humidity. The fan features a novel structure, aesthetically pleasing appearance, and superior performance, characterized by low noise, high airflow, elevated static pressure, and smooth operation.

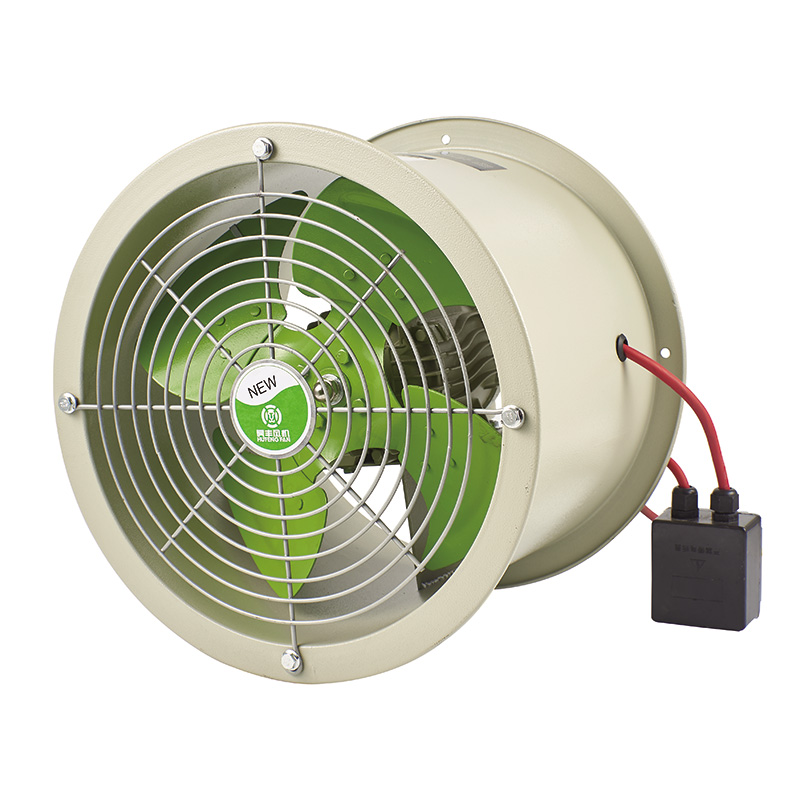

The fan features high wind pressure, high rotation speed, large air volume, mobile convenience, and strong suction. The casing is made of cold-rolled steel with plastic spraying, the impeller is cast aluminum alloy, and the motor is wound with pure copper wire. Manufactured with optimized aerodynamic design and advanced processing technology, it has a lighter structure.

The fan features high wind pressure, high rotation speed, large air volume, mobile convenience, and strong suction. The casing is made of cold-rolled steel with plastic spraying, the impeller is cast aluminum alloy, and the motor is wound with pure copper wire. Manufactured with optimized aerodynamic design and advanced processing technology, it has a lighter structure.

The CBF Explosion-Proof Axial Fan is specialized ventilation equipment for hazardous environments. The fan is composed of an explosion-proof motor, blades, casing, etc. To prevent sparks from friction, the blades are made of cast aluminum alloy.The fan features low noise, low energy consumption, and superior performance. In addition to ventilation and exhaust, it can be installed in spaced series along long exhaust ducts to increase duct pressure. Unlike general fans in structure and material, its applications are similar.

The T40 axial flow fan is suitable for ventilation and heat dissipation in general factories, warehouses, offices, and residences. Removing the casing allows it to be used as a free-standing fan, or it can be installed in spaced series along long exhaust ducts to increase air pressure in the pipeline. According to user needs, this series can adopt an external motor (mounted on the casing) with belt drive in its structure, designated as model KT40. It shares the same performance parameters as the T40 fan, with the primary function of exhausting high-temperature or moisture-resistant gases.

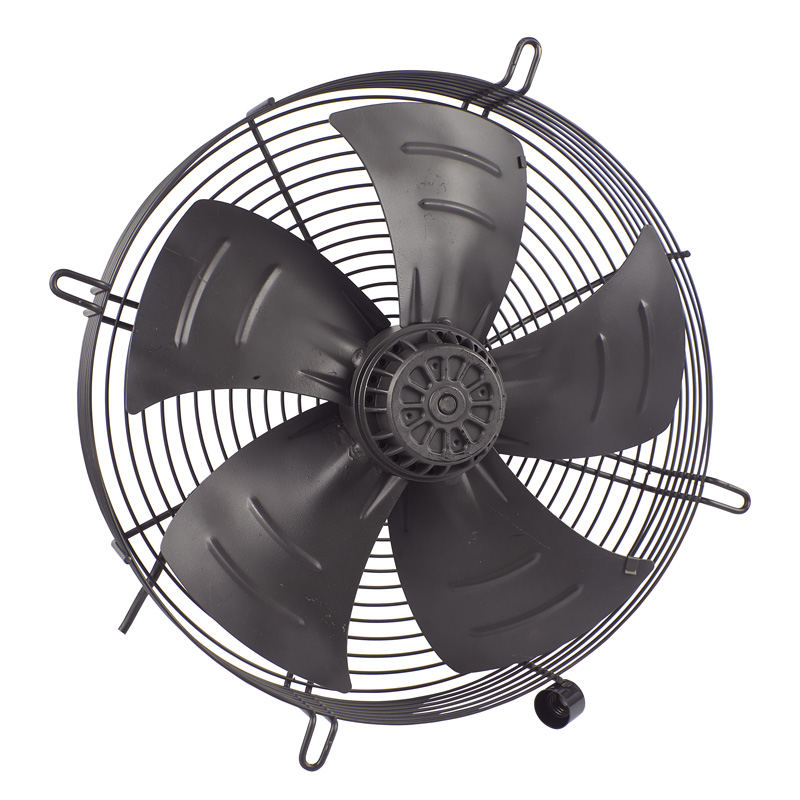

The YWF Series External Rotor Fan is a new product developed by our company through repeated research and trial production. Compared with conventional axial flow fans, this fan features higher efficiency, lower noise, minimal vibration, compact structure, and aesthetically pleasing appearance. The impeller is directly mounted on the outer circumference of the external rotor, resulting in shorter axial dimensions. Its successful development represents a major breakthrough in the field of axial flow fans. This series has obtained multiple national patents.

The YWF Series External Rotor Fan is a new product developed by our company through repeated research and trial production. Compared with conventional axial flow fans, this fan features higher efficiency, lower noise, minimal vibration, compact structure, and aesthetically pleasing appearance. The impeller is directly mounted on the outer circumference of the external rotor, resulting in shorter axial dimensions. Its successful development represents a major breakthrough in the field of axial flow fans. This series has obtained multiple national patents.

The YWF Series External Rotor Fan is a new product developed by our company through repeated research and trial production. Compared with conventional axial flow fans, this fan features higher efficiency, lower noise, minimal vibration, compact structure, and aesthetically pleasing appearance. The impeller is directly mounted on the outer circumference of the external rotor, resulting in shorter axial dimensions. Its successful development represents a major breakthrough in the field of axial flow fans. This series has obtained multiple national patents.

Zhejiang Hufeng Mechanical & Electrical Co., Ltd. was founded in the early 21st century, serving as a original manufacturer with over a decade of expertise in fan production.Located in the Eastern New District of Wenling City, Taizhou, Zhejiang Province—within the municipal industrial transformation and upgrading demonstration zone—the company enjoys superior geographical advantages and convenient transportation, adjacent to expressways. The company boasts strong technical capabilities and abundant human resources, guided by scientific production management. Equipped with first-class CNC machining centers, automatic inspection centers, and two advanced assembly lines. The company specializes in the production of various types of fans, motors and other equipment, and strictly follows the national general fan equipment manufacturing standards in production. Over the years, we have cultivated a professional team for manufacturing fans to provide users with safe, reliable and excellent products.In terms of technology, we concentrate on in-depth research, introduce the latest production technologies at home and abroad, and improve the structure and quality of products. In terms of capital, we increase investment and continuously innovate in products to face market competition. The company adheres to a user-centered approach, providing a series of high-quality, green, environmentally friendly, technological and innovative products.